May

02

May

02

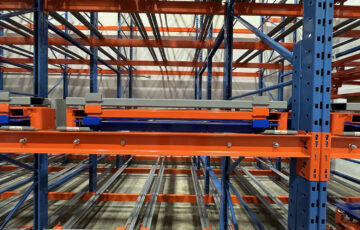

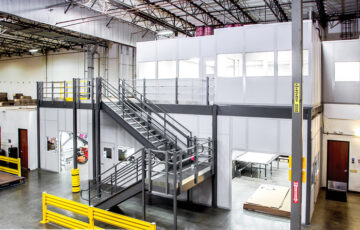

Optimizing Warehouse Efficiency: Pallet Racking & Shelving Porsche Mississauga

Rack Systems Inc. designed and implemented a custom pallet racking and shelving storage system for Porsche Canada’s Auto Parts Distribution Center in Mississauga, Ontario. The objective was to optimize space usage, ensure fast part retrieval, and support the brand’s commitment to operational excellence. Table of Contents Project Overview Porche’s tender requirements for the new 113K […]